Sand blasting is an operation method that uses compressed air to spray brown corundum sand through the blasting equipment at a high speed to the surface of the workpiece to be processed to increase its roughness, thereby enhancing the adhesion between the workpiece and the paint.

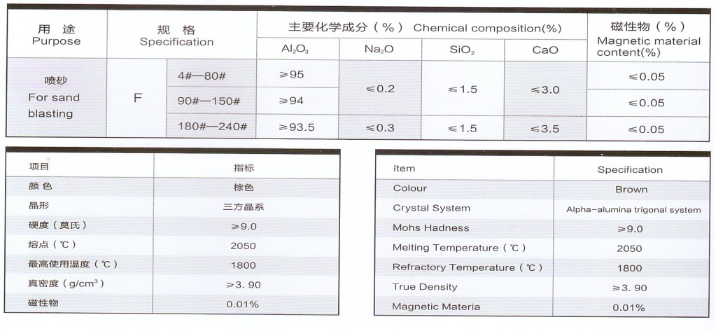

Brown Fused Alumina for Sandblasting is mainly used for various material workpieces to decontaminate, derusting, prevent corroslon, remove oxide skin, light-decorate, process pattern effect and so on. About Brown Fused Alumina for Sandblasting there are three factors the decide the effect of Brown Fused Alumina for sandblasting:

1. The grinding ability: the higher grinding ability, the better for sandblasting.

2. The bulk density: the higher bulk density, the better for sandblasting.

3. The dust: the lower dust, the better for sandblasting.

Brown fused alumina sandblasting features high grinding force, high bulk density and low dust. Brown Fused Alumina with high bulk density and air cleaned, the quality of this kind of Brown Fused Alumina is very excellent for sandblasting.

没有评论:

发表评论