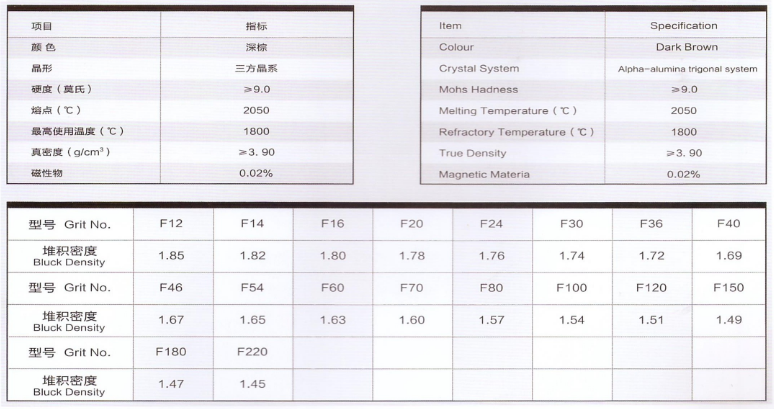

Brown Fused Alumina by roller crushing has high purity, high self-sharpness, good toughness, and extremely low magnetic material content. Grinding tools made from Brown Fused Alumina by roller crushing have sharp grinding, low heat generation rate, high grinding ratio, and less adhesion when used; Density is lower than ball-milled plastic sand, but it has high purity, strong self-sharpness and good toughness.

Why Choose Yu Shi Brown Fused Alumina by roller crushing?

1, high-quality grinding grade alumina

Workers hand-picked high-quality ground-grade alumina for smelting, with Al2O3 content as high as 85%, ensuring quality from the source!

2, secondary refining:

All brown corundum plus secondary refining for 3 hours outside the industry standard smelting time improves product quality!

3, strict classification

The brown corundum blocks after smelting are screened and graded by workers manually to ensure that each batch is a quality product!

4, high-strength magnetic separator

The industry is generally 2 5000 Gaussian magnetic separator, we use 5 13,000 Gaussian magnetic separator to remove ferrosilicon impurities!

5. Corporate strength

The company has operated more than 20 years and the factory has invested over 100 million yuan. Choose us equal to choose quality!

没有评论:

发表评论