The demand for non-shrinkable fused zirconia corundum bricks has been increasing in recent years, with the exception that 41# fused zirconia corundum bricks are almost completely free of shrinkage casting, and oxidizing method 33# is not required for crater-free fused zirconia corundum bricks. There has also been a considerable increase in usage. The production cost of this product is high and the production process is more complicated, so the selling price of the product is higher. In recent years there have also been glass melting furnaces using dense-end cast bricks, which are used in the pool wall area.

The basic principles for the rational selection of fused zirconia corundum bricks:

(1) The wall bricks in contact with the glass melt are oxidized with a 33 # tilted cast zirconia corundum brick. This choice is technically and economically reasonable.

(2) Almost all of the upper structure of the melting furnace can be normally fused cast zirconia corundum bricks, and its function is fully enough.

(3) For the furnace with kiln bottom insulation, the 75mm-thick oxidizing method with 33# non-shrinkage AZS bricks is most suitable for the kiln floor surface, and it is used in combination with the zirconium corundum ramming material.

(4) The side walls, flat borings and inclined rakes of small furnaces are generally made of 33 # zirconia corundum bricks with common casting reduction method, and the bottom of the furnace can also be made of 33 # zirconia corundum bricks without shrinkage or dense casting.

(5) The wall of the clarification department is preferably made of ordinary cast α-β alumina bricks, and the kiln bottom is preferably made of α-β alumina bricks without shrinkage casting. The cost of such selected furnaces is higher and can also be used. Oxidation method 33 # AZS brick instead.

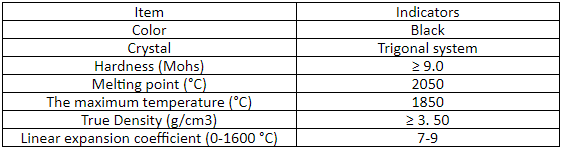

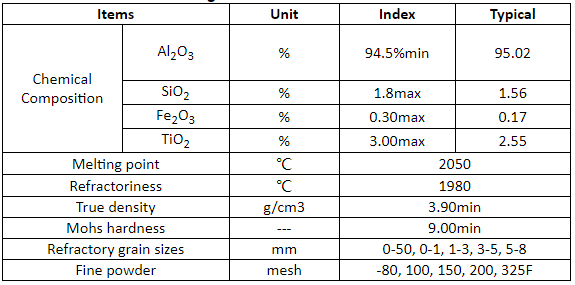

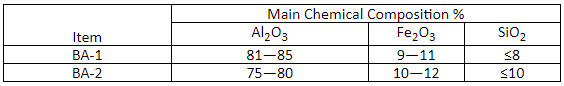

Black Fused Alumina has characteristics of moderate hardness, high toughness, high temperature resistance, and stable thermal stability. and it is mainly suitable for free grinding, such as coarse grinding before electroplating products, mainly for polishing and sandblasting of stainless steel, fabricated metal products.

Black Fused Alumina has characteristics of moderate hardness, high toughness, high temperature resistance, and stable thermal stability. and it is mainly suitable for free grinding, such as coarse grinding before electroplating products, mainly for polishing and sandblasting of stainless steel, fabricated metal products.